Inventory: Does Your Sawtooth Make You Smile?

Some of the levers that drive inventory levels and management are easier to pull than others. An Inventory Planning system is certainly helpful because it constantly reviews your positions, effectively driving-out the review cycle time.

But an Inventory Planning system isn’t required to manage your inventory better.

The Key Factors of Inventory Management

The key factors of your inventory management needs are generally related to the following:

- Cycle Service Level (% of time an order ships on-time/in-full)

- Replenishment Leadtimes (PO placement to Inventory Receipt)

- Variability in Replenishment Leadtimes

- Vendor Performance

- Transportation Times

- Warehouse Handling Times

- Demand Forecast

- Demand Variability

- Frequency of Inventory Review

- Purchase Quantity Requirements (Minimum Order Quantity, Order Multiple, etc)

- Safety Stock Method

- Network Strategies

The Factors of Replenishment Lead Time

The parameters and factors of inventory management can all be measured and used for a more statistically-driven approach.

Let’s talk about Total Replenishment Lead Time, which includes:

- Vendor’s Required Order Lead Time: From the time you place a PO to the time the product is available for them to ship

- Transit Time: From the time the product is ready to ship from the vendor to the moment it arrives at your warehouse

- Warehouse Turn Time: How long it takes the warehouse to receive your product, put it away, and enter it into the system for shipment to your customers

- AND Your Inventory Review Interval: This one is important because it’s one of the easier parameters to change. If you review your inventory positions (by product) each month, you can drop your inventory needs by 2 weeks if you review them every 2 weeks.

The Inventory Sawtooth Pattern

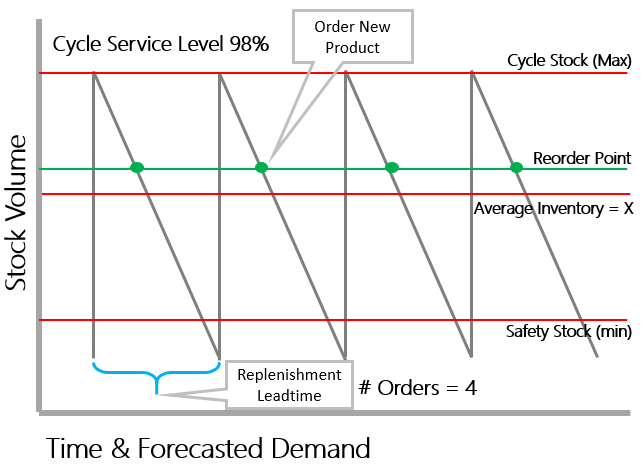

The behavior of your inventory, over time, creates the aptly-named “Inventory Sawtooth”.

In the example graphs above you can see how reducing the Replenishment Lead Time can drop your overall inventory needs.

Note: This is a simple sawtooth pattern example for illustrative purposes – the actual ability to reduce inventory depends on many factors of inventory management.

Help With Better Inventory Management

Our Advisors can help you navigate the landscape of inventory management in the ways that work best for your business, and help you implement systems to do it even better.

For more information on inventory management practices and how we’ve helped clients make meaningful impacts in their business, check out our case study: “Inventory: Not Just A Feeling.”

Contact us at info@waypostadvisors.com or send us a message