Opportunities & Action: Procurement & Sourcing

How do you know if you are paying a competitive price to your vendors? Do you feel blindsided by price changes? Here we provide an outline of recommendations and questions to ask your procurement team so you can work towards putting the "strategic" back into your sourcing efforts.

Do you experience these pain points?

- Struggling to get materials on-time or at all

- Unplanned increased prices or greater than planned costs

- Concerns around paying uncompetitive pricing

- Late or long-lead time deliveries

- No sense of how well key suppliers are performing

The supply chain realm is riddled with potential challenges that can disrupt business flow. Are you consistently grappling with the headache of not receiving materials on-time or perhaps not getting them at all? Unanticipated surges in prices or costs that exceed projections can significantly strain budgets. There's also the looming worry about whether you're being subjected to uncompetitive pricing. Delays in deliveries, especially those with long-lead times, can put production timelines in jeopardy. And without a clear gauge on how well your key suppliers are performing, you're essentially navigating blind. Recognizing and addressing these prevalent pain points is the first step towards a smoother, more efficient supply chain operation.

Do you feel you have the right processes and tools?

- Perform spend analysis by SKU and supplier

- Identify and track spend with critical SKUs/suppliers

- Implement robust SIOP process

- Track market conditions, gather market intelligence

- Establish contracts with key suppliers

- Multi-source where it makes sense

- Strategic Purchasing vs. Buyers

Ensuring efficiency in supply chain management hinges on adopting the right tools and processes. Ask yourself, do you frequently perform a spend analysis by SKU and supplier? Can you swiftly identify and monitor your expenditures with crucial SKUs and suppliers? Embracing a robust Sales, Inventory & Operations Planning (SIOP) process can refine forecasting and supply chain alignment. To avoid price and input disruptions, it's imperative to consistently track market conditions and amass valuable market intelligence. Strengthening ties with central partners often means establishing firm contracts with key suppliers. Moreover, exploring opportunities to multi-source is vital to a robust supply chain. By evaluating and integrating these processes and tools, businesses can navigate the supply chain maze more effectively and competitively.

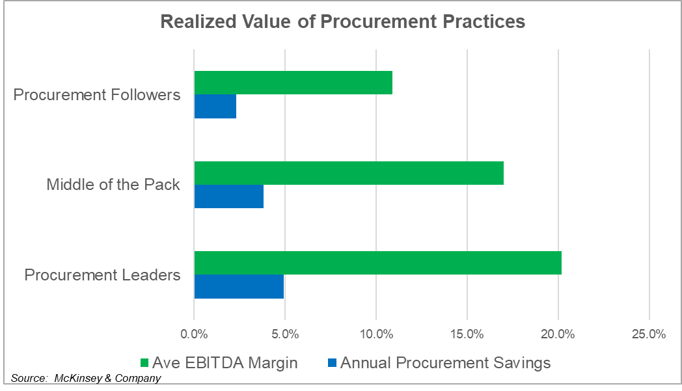

Why sourcing strategies matter

Exploratory questions to ask your team

- What insights do we have about supplier spend and criticality?

- How have we leveraged data to help us understand our greatest opportunities for improvement?

- How are suppliers for each category managed?

- What are the KPIs that define and measure procurement & supplier success?

- How are strategic suppliers managed?

- Where is it not possible to be multi-sourced?

In the evolving world of supply chain dynamics, understanding supplier management is paramount for businesses, large and small. How do you dissect supplier spend patterns? What role does data play in spotlighting operational growth zones? It's essential to drill down into supplier management techniques across various categories and set clear KPI benchmarks for procurement efficacy. Especially when dealing with pivotal suppliers, a tailored management approach can make all the difference. Moreover, recognizing areas where diversifying suppliers is a challenge can help in risk mitigation. By focusing on these pivotal areas and integrating strategic questioning, businesses stand to gain a competitive edge in their supplier relationships, ensuring efficiency, transparency, and profitability.

Recommended KPIs

- Purchase Price Variance

- Supplier On Time Delivery and Quality

- Cost-Savings (continuous improvement)

- Contract performance

- Supplier Scorecards