Thinking Strategically About Freight: The Role of Supply Chain Consulting in Gaining More Margin

There’s no denying the fact that freight and storage are a cost that can be somewhat unpredictable and highly impactful to your margins if not thoughtfully approached.

If you are a company that offers delivered pricing to your customers for long-ish periods of time (greater than 6 months), it’s worth understanding how the freight portion of your delivered pricing quotes are contemplated and putting review processes in place to quickly identify when logistics pricing is off-the-rails (pardon the pun). Engaging supply chain consulting firms can provide the strategic insights and advanced technologies needed to manage freight effectively and improve overall supply chain performance.

Understanding the Supply Chain

The supply chain is a complex network of organizations, people, and activities involved in the production and delivery of a product or service. It encompasses the entire value chain, from raw materials to end customers, and involves various stakeholders, including suppliers, manufacturers, logistics companies, and distributors. Understanding the supply chain is crucial for businesses to identify areas for improvement, optimize operations, and gain a competitive advantage. By having a clear view of the entire value chain, companies can pinpoint inefficiencies, streamline processes, and enhance collaboration among all parties involved. This holistic approach not only boosts operational efficiency but also strengthens the overall resilience of the supply chain.

The Importance of Freight in Supply Chain Management

Freight plays a critical role in supply chain management, as it enables the movement of goods from one place to another. Effective freight management is essential to ensure timely and cost-efficient delivery of products to customers. Logistics companies and supply chain companies must work together to optimize freight operations, reduce costs, and improve customer satisfaction. By streamlining freight management, businesses can improve operational efficiency, reduce transit times, and increase the reliability of their supply chain. This collaboration between logistics and supply chain companies is vital for maintaining a resilient supply chain that can adapt to market changes and meet customer demands consistently.

Delivered Pricing

Delivered Pricing is when the price to your customer includes everything it takes to deliver the product, including fully-loaded product cost, transportation & logistics, and margin. The validity of this pricing term will drive the inherent risk: The shorter the commitment (say, one month), the lower the risk. If you're offering delivered pricing for 6+ months, you're taking the risk of fluctuations in cost, which could significantly erode your margin if you're not paying close attention. It also takes the risk away from the customer, which is a creation of value for your customer.

The Value Chain Of Delivered Pricing

It's important to remember that Delivered Pricing provides an inherent value to your customers. There's a value in absorbing the risk of freight fluctuation, as well as arranging the transportation and dealing with the troubleshooting requirements so your customer doesn't have to.

Another option would be to ask your customer if the freight portion of the pricing can “float”. You would still provide the logistics service but would be allowed to adjust the pricing based on actual freight rates. Some thought is required for how to put this into practice, depending on your internal systems. And, of course, it's imperative to implement some sort of freight review on an ongoing basis to ensure the pricing is adjusted accordingly.

Definitions & Supply Chain Management Recommendations

Disclaimer: This information is based on US freight dynamics only.

More definitions: Spot Market and Contracted Rates.

The Spot Market refers to market rates at a moment in time, which (for trucking and container freight) will fluctuate based on relative dynamics of supply (capacity) and demand. These dynamics can be very regional, specific to modes (truck, rail, container, etc.), and relative to diesel pricing for a specific region.

Contracted Rates refer to rates that have been agreed between a shipper (the company with the goods) and the carrier (the trucker, container line, etc) and are valid for a period of time (longer-term than Spot Market). In almost all cases the fuel portion of the rate will float with the diesel market, but the line-haul freight portion should be held steady for the term of the agreement. These agreements usually also include volume commitments from the shipper (ie: 10 trucks per week to get that rate).

The key strategy, like many of us know from managing our financial portfolios, is to diversify. Use a blend of Spot Market rates and Contracted Rates to ensure you have some predictability in the pricing, but that you can also take advantage of down-market fluctuations and capture more margin.

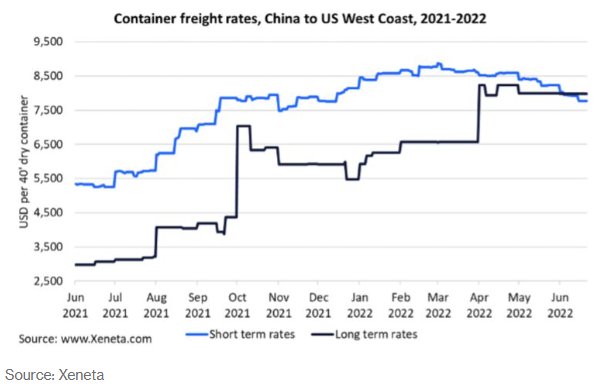

Truck and container freight markets are very responsive to macroeconomic factors such as demand and supply. Keeping in touch with economic outlooks on a rolling 12-month basis is an important indicator for when it might make sense to change the distribution of your portfolio between spot and contracted rates.

Inventory Management and Freight Strategy

Inventory management and freight strategy are closely linked, as the movement of goods is often triggered by inventory levels. A well-planned inventory management strategy can help businesses optimize their freight operations, reduce costs, and improve customer satisfaction. By implementing just-in-time inventory management, businesses can reduce inventory holding costs, minimize stockouts, and improve their ability to respond to changing demand patterns. A freight strategy that is aligned with inventory management can help businesses optimize their logistics operations, reduce transit times, and improve the reliability of their supply chain. This alignment ensures that inventory levels are maintained at optimal levels, reducing excess stock and enhancing the overall efficiency of the supply chain.

Source: Supply Chain Latest: Ocean Freight Rates Are Falling – Bloomberg

Today's Relevant Supply Chain Example

Given that US full truck freight rates are at or near “bottom”, it's a good time to think about contracting. If you are willing/able to commit to volumes for 6-12 months, you could secure lower, predictable rates, even if the spot market increases. Since the market appears to be close to bottom, spot market rates are not likely to fall much further, if at all. This means that there's not a lot of additional margin to capture from playing the spot market, and it will be to your advantage to have predictable rates for 6-12 months.

When the market goes the other way, you may want to consider letting a larger portion of your portfolio float with the spot market. This will also allow you to capture margin gains.

The Freight Chess Board for Logistics Companies

If your logistics department doesn't have bandwidth to think strategically about playing the chess board of macroeconomics (and who does when you work in logistics?), perhaps a Fractional resource could be a good option for your team. There are many other logistics management optimizations and strategies that could drive improved margin and service performance to your customers, and a Fractional resource is a great way to access that knowledge and implementation ability.

Measuring Success and Case Studies

Measuring the success of supply chain operations is critical to identify areas for improvement and optimize operations. Key performance indicators (KPIs), such as on-time delivery, inventory turnover, and supply chain costs, can be used to measure the effectiveness of supply chain operations. Case studies of successful supply chain transformations can provide valuable insights into best practices and strategies for improving supply chain operations. For example, companies like Amazon and Walmart have implemented sustainable supply chains that have improved operational efficiency, reduced costs, and enhanced customer satisfaction. By studying these case studies, businesses can learn from the experiences of others and develop strategies to improve their own supply chain operations. These real-world examples highlight the importance of continuous improvement and innovation in achieving a resilient and efficient supply chain.