Network Optimization: Give Yourself A Raise

What would need to be true to make more money without selling an additional unit or increasing prices? Or perhaps to improve the level of service to your customers without adding costs?

Either way, there could be hidden opportunities in your sourcing or distribution network such as:

- Unnecessary Transportation costs

- Sub-optimized shipment quantities – Higher cost per unit shipped & more damages

- Distribution Center locations that are long distances from customers

- Unnecessary Storage (warehousing) & Handling costs

- Storing inventory in multiple locations, especially for slow-moving inventory

- Sending inventory from a plant to a DC and then onto a forward warehouse

- Duplicative Inventory & Excessive Shrink

- Serving a small number of customers from each location increases inventory needs

Network Optimization: Give Yourself A Raise

Network Optimization: Give Yourself A Raise

- Inventory shrink from damage/loss increases with small shipments & additional sites

- Service Level Penalties

- Customer penalties for late or short deliveries

- Delivery performance improves as travel distances decrease

Consider this real world example:

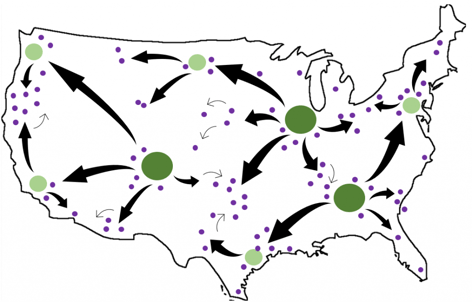

A privately-held, $500M manufacturing & distribution company had a hypothesis that their distribution network was overly complicated and driving up their costs. They wanted to operate at a best-in-class level and drive down costs without sacrificing the level of service to their customers.

With the help of an Advisor they were able to assess their distribution network and identify multiple opportunities to reduce costs and improve service, such as

- Warehousing in locations that minimized the distance to the customer served

- Reduced cost per ton-mile of transportation

- Improved level of service to customers

- Consolidating warehouse locations to reduce the total amount of inventory required in the network, thus reducing carrying costs, shrink, obsolescence risk, FIFO risk

- Reducing inventory transfers from distribution centers to forward warehouses

- Eliminating inventory storage locations specific to individual customers (unless justified by pricing and strategy)

The Company also found that they had sub-optimal movements such as imports from overseas that were brought into the Midwest, only to be unpacked and shipped back out to a location on the coast. They worked with their suppliers and customers to create direct shipments that significantly reduced their costs.

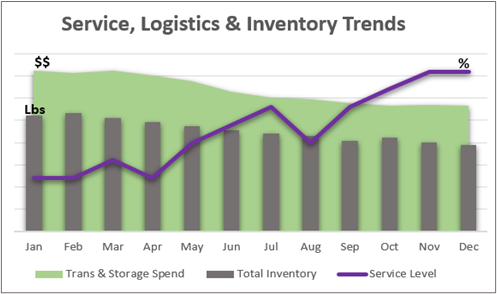

As a result of this work they were able to reduce their annual transportation and storage spend by 14%. They also improved their On-Time delivery to customers by 8% while simultaneously reducing their inventory by 15%.

Network Optimization allowed them to provide a better level service to their customers while also giving themselves a raise.

This is the experience our Advisors can bring you.

Want to learn more about how you can drive impressive business performance at your Company? Contact us at info@waypostadvisors.com, or check out our Services & Expertise.