Starting Strong with Supply Chain Success: A Guide to Supply Chain Consulting

Embarking on a new business journey is exciting, but the road to success often begins with overcoming the challenge of translating aspirations into a concrete plan. Sometimes, the only thing standing between your business and success is knowing how to move forward.

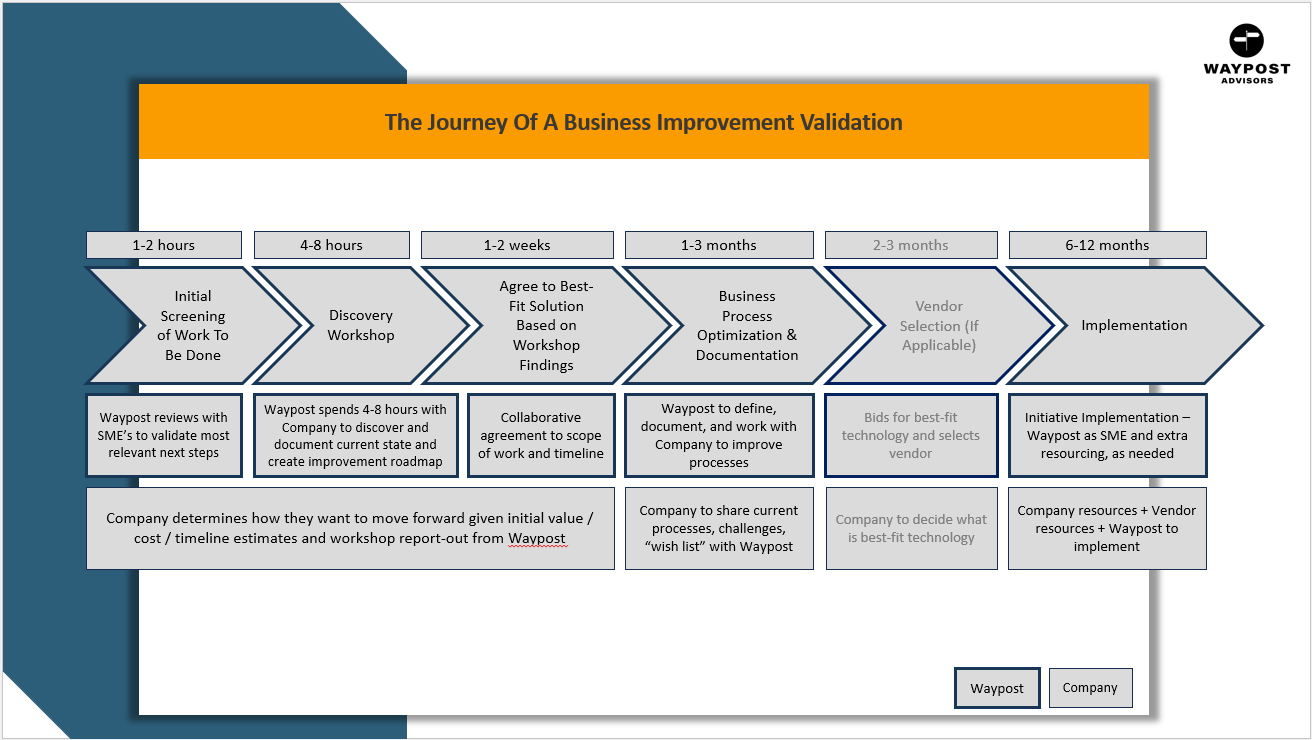

When you begin a new journey to grow your business, improve your performance, or implement something new, putting pen to paper on the plan can sometimes be the hardest part. At Waypost Advisors, we understand that starting strong with your supply chain success involves more than just ideas; you must be able to create a strategic roadmap that turns ambitions into achievements.

Over the years, our extensive experience working with various companies has led us to develop a structured process that offers clear direction and serves as a launchpad for initiating and expediting progress toward business objectives. We strongly advocate collaborating with supply chain experts who can provide valuable insights by drawing on the successes and lessons learned from similar projects in other businesses. This collaborative approach helps your organization ensure the success of your initiatives while helping you steer clear of potential pitfalls. Leading supply chain consulting firms offer comprehensive assessment processes and implementation strategies that extend beyond mere recommendations to include tangible operational support and advanced technology integration.

What is Supply Chain Management?

Supply chain management (SCM) is the backbone of any successful business, encompassing the planning, implementation, and oversight of the flow of goods, services, and information from raw materials to the end customer. This intricate process involves coordinating various activities such as procurement, production, logistics, and distribution. Effective SCM is not just about moving products; it’s about creating a competitive advantage and enhancing customer satisfaction. By streamlining these processes, companies can respond swiftly to market changes, reduce operational costs, and boost overall efficiency. In essence, supply chain management is about ensuring that every link in the chain works harmoniously to deliver value to the customer.

Steps to Initiate Improved Supply Chain Management Success

1. Define the Problem, Not the Solution.

As industry-experienced supply chain consultants, we frequently get inquiries from companies about whether we can help them with a specific activity. They may call us and say: “We need to implement a WMS” or “We need to consolidate warehouses”. When we get these questions, we always recommend starting with the problem you’re trying to solve. Explore the assumptions that led you to that conclusion, collect data to validate the assumptions, and deep-dive the business processes to the root cause of the problems you’re experiencing. We have helped clients avoid tens of thousands of dollars in unnecessary expenditures simply by focusing on improving their internal processes and accountability structure before investing in tools and technology they couldn’t effectively use.

2. Take Them to the (Work) Shop.

Get a peek under the hood and have an expert in the field of focus spend 4-8 hours walking a day in the shoes of the people who are involved. They should physically walk the processes (if applicable), observe how end-users use systems and information and how they make decisions, and map the end-to-end processes that are in scope. This can really help you to define the problem and what’s needed to improve it, and avoid jumping to a conclusion that may be over-engineered, cumbersome, or costly.

3. Begin With Improving Processes.

Once you have a gap analysis of what you need versus what you have, work to shore up the processes as much as possible. You may find that fixing processes and roles/responsibilities solves a significant portion of the problems you’re seeing. If you’re considering implementing a technology, the saying goes: “You cannot automate bad processes.” If you invest in technology before having a defined, repeatable, and sustainable process in place (oh yes, and clean data), you will not be able to capture the value of the technology or, worse, the technology will be reduced to nothing more than an expensive way to disengage your workforce. Effective inventory management is crucial in streamlining operations and ensuring that your processes are efficient and cost-effective.

4. Bonus: Evaluate Technology Based-On What You Need, Not Who Sells It Best

If part of your improvement and business growth journey involves technology, ensure you are using a request for proposal (RFP) process that selects for your unique needs rather than trying to shoehorn your business needs into the capability of the process. Using a system-agnostic facilitator, such as Waypost Advisors, can be an effective way to ensure your needs are met without falling victim to a sexy sales pitch. Additionally, evaluating digital capabilities can significantly enhance supply chain efficiency by integrating advanced technologies like factory automation and data analytics.

Read: Tips For Supply Chain Continuous Improvement Success

Our experienced team of supply chain consultants finds great satisfaction in guiding our clients through these transformative journeys. When you partner with us, you’re not just getting a service; you’re gaining a dedicated collaborator committed to the success of your initiatives. Reach out to us today, and let’s embark on this journey together. Whether your organization needs temporary expertise or interim staffing, our experts are ready to support your initiatives and elevate your organization to new heights.

Waypost Advisors* is an end-to-end supply chain and resourcing solution. We offer expertise in procurement, inventory, project management, planning, transportation & warehousing to fit the needs of your B2B manufacturing or distribution company. Our advisors can provide you with the resources and expertise to tackle your supply chain challenges while allowing you to still focus on running your business.*

Building a Strong Supply Chain

Building a robust supply chain is a strategic endeavor that requires careful planning and execution. The first step is to define a clear supply chain strategy that aligns with your business goals. This involves identifying key performance indicators (KPIs) to measure success and establishing a governance structure to oversee supply chain operations. A resilient supply chain network is essential, incorporating a diverse range of suppliers, logistics providers, and distribution channels. This network should be designed to adapt quickly to market fluctuations. Investing in digital technologies, such as artificial intelligence and data analytics, is crucial for real-time visibility and continuous improvement. These tools enable companies to monitor and optimize their supply chain operations, ensuring they remain competitive and responsive.

The Impact of Technology on Supply Chains

Technology is revolutionizing supply chains, making them more efficient, responsive, and transparent. Digital technologies like artificial intelligence, blockchain, and the Internet of Things (IoT) are at the forefront of this transformation. AI-powered predictive analytics help companies forecast demand and optimize inventory levels, reducing costs and improving customer satisfaction. Blockchain technology enhances supply chain transparency and security, ensuring that every transaction is recorded and verifiable. Meanwhile, IoT devices provide real-time tracking of shipments and inventory, allowing companies to respond swiftly to disruptions. By leveraging these digital tools, companies can achieve greater operational efficiency and maintain a competitive edge in the market.

Creating a Sustainable Supply Chain

In today’s business environment, creating a sustainable supply chain is not just a moral imperative but a strategic advantage. A sustainable supply chain minimizes waste, reduces carbon emissions, and promotes fair labor practices. Companies can achieve this by adopting sustainable procurement practices, reducing energy consumption, and encouraging recycling and waste reduction. Digital technologies, such as data analytics and AI, play a crucial role in this transformation by providing real-time visibility and enabling continuous improvement. By focusing on sustainability, companies can reduce their environmental impact, enhance social responsibility, and improve their reputation. Moreover, sustainable supply chains often lead to greater operational efficiency and cost savings, proving that doing good can also be good for business.